5 Axis CNC Machining Services

Specialize 5 Axis CNC Milling Services

Start With A Free Project Review

5 Axis Machining Services

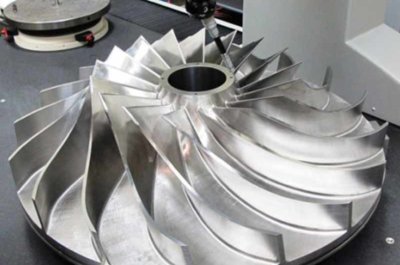

For time-sensitive and complex machined parts, Superapid’s 5-axis CNC machining service offers unparalleled speed and flexibility. Our seasoned professionals can help in making your ideas into a reality. We work from rapid CNC Machining to end-use components for safe-critical applications. Our 5-axis milling capabilities provide you precise parts with complex geometry.

Advantages of 5 Axis CNC Machining Services with Superapid

Quick turnarounds

With 20 sets of 5 axis equipment in-house, we hold the capacity to shape your prototypes and manufacturing parts in days.

High-quality 5 axis CNC machining services

Our machinery includes JingDiao and HAAS 5 axis CNC machines, with one on-site inspection system to get super-tight tolerances.

Expertise and experience

With over a decade of experience in the machining sector along with comprehensive knowledge of material features, we know how to tackle the most complex parts; irrespective of the medium.

Compatibility with industry

From aerospace components to high-tech electronic items, we have worked with different companies across the manufacturing spectrum.

Applications of 5 Axis CNC Machining Services

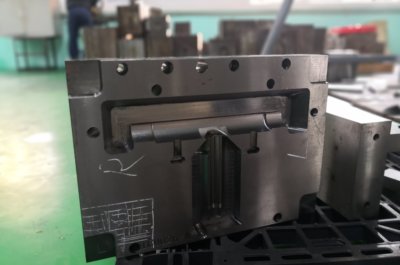

Automotive

5 axis CNC machining services is widely used in the automotive sector for the production and prototyping of car parts.

These components include:

- Valves

- Inspection jigs

- Engine housings

- Engine covers

- Light guides

Understand the Process of 5 Axis CNC Machining

5 axis machining is a kind of CNC machining in which a cutting tool can move around five axes rather than the usual three.

Benefits of CNC turned parts service

Simultaneous 5 Axis Machining or 3+2 Axis Machining

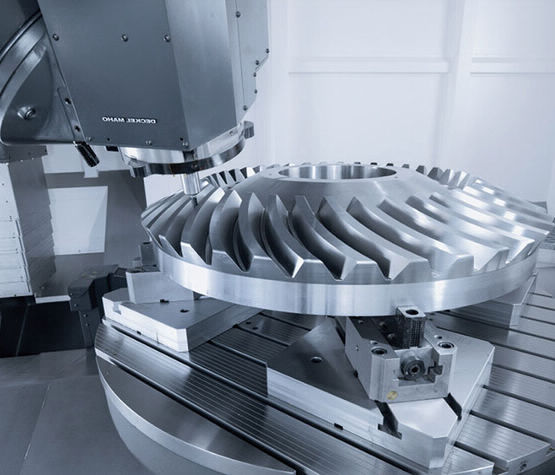

5 axis CNC machines importantly differ from one another. Some 5-axis CNC machines use simultaneous 5-axis machining, while others employ a “3+2-axis” technique.

Simultaneous 5 axis

Simultaneous or continuous 5 axis CNC machining is a type of 5 axis machining where the machine can adjust movement continually on all five axes without break. Simultaneous 5 axis CNC can be lightning-fast because there is no break between passes of the cutting tool.

3+2-axis

Another type of 5 axis machining is 3+2-axis. Here the machine can move only on the 4th and 5th axis when the tool isn’t moving along the conventional three axes. This form of 5 axis CNC machining can be slower but result in more rigid components and longer tool life.

Trunnion-Style or Swivel-Rotate-Style

5 axis CNC machining services can have different configurations. All have spindles that travel along the X, Y, and Z axes, but machines can add the two “extra” axes in different ways.

The most common types of 5 axis CNC machines are trunnion-style machines and swivel-rotate-style machines. Some machines combine features of both.

Trunnion-style 5 axis machine

A trunnion-style CNC machine is a CNC mill with a moving table. That angle of the workpiece linked to the table is adjustable, allowing the cutting tool to strike the material from multiple angles.

Trunnion-style CNC machines have A-axis and C-axis. Their benefits include effective removal of heavy materials, better undercut access, and a bigger overall work volume.

Swivel-rotate-style 5 axis machine

A swivel-rotate-style 5 axis CNC machining services is a form of CNC mill having a rotating spindle. Adding a B and C axis to the spindle permits the cutting tool to strike the material from various angles, but in a different style to a trunnion machine.

Benefits of swivel-rotate-style 5 axis CNC machining services include the capability to handle heavy components, since the table remains constant— effectively minimizing chatter and increasing accuracy.

With a 3-axis machine, the spindle moves down and up, back and forth, and side to side. 5 axis CNC machines, besides, have two more axes. Either the table goes side to side on two different axes or simply spindles itself and swivels on two axes.

Both these methods allow the cutting device to approach the workpiece from a greater number of angles and make it possible to generate highly-complex shapes.

It further reduces the number of required setups. Machinists don’t need to turn the workpiece manually; because the cutting tool can reach more places.

Benefits of CNC turned parts service

Cylindrical parts

CNC turning machine is perfect for creating cylindrical or round parts. Lathes make these parts accurately, quickly, and with tremendous repeatability.

Range of processes

Although typically used for components of a particular shape, CNC turned parts service can still be used for a variety of cuts, including boring, drilling, knurling, and threading.

Professional quality

We provide you high-quality CNC tuned parts in the most competitive rates.

CNC turning metals

Aluminum CNC machining is a key part of Superapid’s services catalog; however, CNC turning can be used as well, to process metals like steel, magnesium, brass, copper, stainless steel, titanium, bronze, and nickel alloy.

CNC turning is used commonly for aspect and mechanical components. These are often manufactured from aluminum, the most machinable metal. An aluminum part can be produced with high accuracy and strength, as well as a superior surface finish.

CNC turning plastics

While accuracy machining is normally utilized for metals, Superapid can likewise give CNC turned parts services to plastic parts. Materials are accessible for CNC turning to incorporate nylon, polycarbonate, ABS, POM, PP, PMMA, PTFE, PEI, PEEK, giving more precise parts than 3D printing.

5 axis CNC Machining Services FAQ

What are the 5-axes on a CNC machine?

The axes determine the directions where the cutting tool can move when producing parts. There are conventional three-dimensional axes. While the 5 axis machine’s cutting tool can also rotate to approach the part from two directions that serve as two additional axes.

When does 5 axis machining make sense?

Because of the adaptability offered by 5 axis machining, it ought to be utilized to make the most unpredictable shapes and subtleties in parts. The strength of the apparatus additionally gives a smoother and more reliable completion.

Can 5-axis offer tight tolerances?

5 axis CNC machining services is among the advanced manufacturing technologies. So, it can make the tightest tolerances possible, even on detailed and complex parts.