Rapid CNC Machining for Prototyping & Production

Make your parts right, make your parts fast.

Start With A Free Project Review

Best CNC Machining China

Superapid provides different CNC machining services including CNC turning Services, CNC Milling Services and wire EDM, and surface grinding. With our precision CNC machining China, together with other technological capabilities and experienced team, we can handle every technical aspect of creating your parts prototypes, so you can only focus on sending your product to market.

If you need a company well-versed in providing precision CNC machining services China for metal and plastic CNC machining parts, Superapid is the way to go. Contact us to get your manufacturing details and solution.

CNC Machining Services China

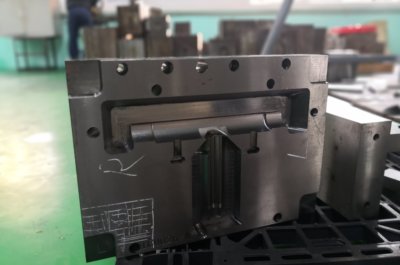

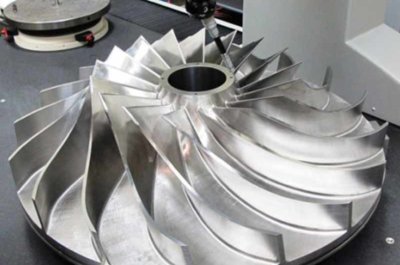

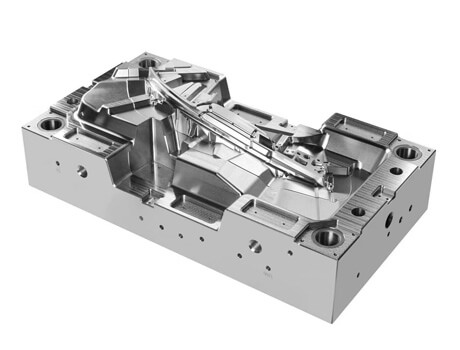

As compared to CNC turning service, CNC milling Services, especially 5-axis milling is used to create difficult 3D shapes or for the application of machined features to parts made; both metals and plastics. The benefit of multi-axis milling machines makes the process of CNC milling versatile, accurate and repeatable, for making many types of part features of complex geometries. These include curves, slots, holes, shapes, angled, and channels. Milling is ideal for creating tooling for plastic injection molding and pressure die casting.

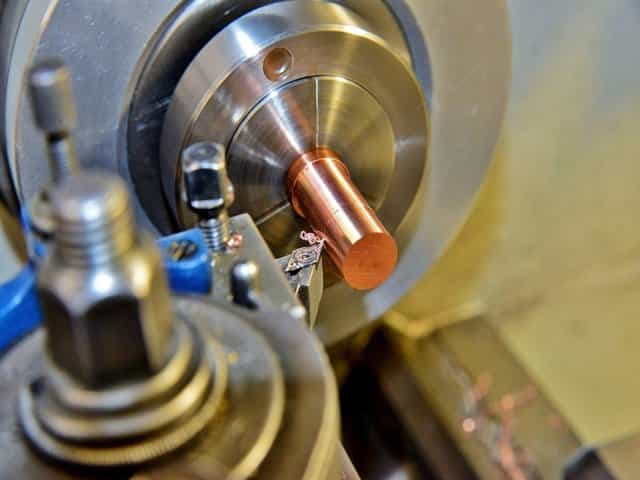

CNC Turning Services

CNC lathe machine allows us to obtain high-speed CNC turning of both metals and plastics from block or bar material. Our CNC turning services allow you the production of complex internal and external geometries, including creating all types of threads. For every component, which is round-shaped, for example, worms, spheres, shafts; CNC turning is an efficient technique compared to CNC milling Services. Superapid’s capacity of providing CNC turning services can make prototypes all the way through mass production parts.

Our Advantages of CNC Machining

There are many service providers regarding precision CNC machining services China. Why should you choose us? The following are some main reasons:

1. Experience

Our technical staff has built up deep, rich experience from several projects. They can handle precision and complex parts in different industries without any issue.

2. Advanced Equipment

Superaid has massive in-house equipment for both production and testing. We will manufacture and inspect your required parts with our advanced in-house machinery, including 5-axis CNC milling services and HAAS 3-, 4-, 5Olympus XRF analyzer, and Hexagon CMM.

3. Fast Turnaround

We return, on average, orders within 24 hours, ship parts within 7 days or less, and we have a 99% response rate regarding on-time delivery and quality rate.

Applications of CNC Machining China

Design & Rapid Prototyping

Despite the assembling procedure used to make the end-use part, CNC machining China is generally utilized by creators as a method for making early and late-stage prototypes with short turnarounds times. CNC prototyping permit planners to quickly emphasize thoughts without tooling expenses or holding up occasions.

It is probably the most ideal approach to make an idea model and function prototype to verify the plan. Contrasted and other quick prototyping strategies, fast CNC machining services China permits us to get tight resilience prototypes in genuine materials quickly.

CNC Prototyping is the favored choice to bring new plan life among the other quick prototyping strategies, except if the items are intended for 3D printing or different techniques as it were.

China CNC Machining Services Tolerances

With a broad range of CNC machines, we can provide standard-tolerance CNC machined parts within the economic price and super precision machined parts for all high-end products. When working with Superapid, we guarantee your specification will be taken care of.

Precision CNC Machining China

Superapid also offers high-quality precision machining service. Along with high precision turning and milling machines, we have the capacity of catching super tight tolerance for prototype production and machining.

Being in the CNC industry for over a decade, we have discovered a simple formula to offer precision machining service

Precision machines + Precision heart = Precision parts.

We have a wide range of CNC machines and seasoned engineers who never compromise with part or tolerance quality.

China CNC Machining Services Materials & Finishes

If you need to manufacture your parts with CNC machining China, it is vital to know the kind of finishes and materials you can apply to your CNC machined parts. We can also apply all types of finishes to CNC prototype parts and production parts thanks to our surface finishing partners. Need custom CNC parts with a high-quality appearance? We are here to help.

CNC Materials

Plastic: HDPE, PS, PAGF30, POM, DHPE, ABS, PP, PPS, (Acrylic), PCGF30, Teflon, PC, ABS+PC, PEEK, PMMA.

Metal: Steel, Aluminum, Stainless Steel (17-4, Inconel 625 & 718), Titanium, Zinc, Magnesium, Bronze, Brass, Copper.

These are rated as the common materials for CNC production parts and prototyping. Besides, we work with all types of machinable metal and plastic and we can buy from the stock market.

What’s more: We can create customized plastic blocks or bars for the material like PPS GF50and PA GF50. To know further plastic materials, contact our team.

CNC Finishes

As-Machined: The most cost-efficient and popular way for inner operational components. Even and fine tool path is good too, for aspect parts.

Bead Blasted: The part is left with matt appearances. A range of 320 to 120 beads allows us to make different roughness to the surface.

Anodized: Type II makes an abrasion-resistant finish. Parts can be anodized in multiple colors— black, red, clear, and blue are most common. It is typically associated with aluminum’s low silicon element series.

Type III is comparatively thick and generates a layer of wear-resistant besides the corrosion resistance seen with Type II.

Powder Coat: This is a procedure where powdered paint is splashed onto a section which is then prepared in a broiler. This makes a solid, wear-and-consumption safe layer that is tougher than standard painting strategies. A wide assortment of shadings is accessible to make the ideal tasteful.

Overview: What's CNC Machining Services?

What is CNC machining?

It is a manufacturing method for removing material. It utilizes sharp cutting tools in a variety of sizes and shapes, which are controlled precisely by a computer. CNC stands for Computer Numerical Control.

Working of CNC Machining

CNC machining begins with a computer, on which engineers prepare a part through CAD (Computer-aided Design) software. This digital component is converted into a format, which you can recognize by a CNC machine.

Instructions are relayed to the CNC machine through “G-Code” after which, the machine starts cutting.

Several CNC machines have a “work-table” and work holding machine to retain a block of material known as the “workpiece” — in place. The worktable may (or may not) move, depending on the machine’s style.

When machining kicks off, the cutting tool creates contact with the workpiece, cutting layers of material away. The tool or workpiece is moved or rotated rapidly as per the G-Code instructions and cuts are made in the right places until the part is finished.

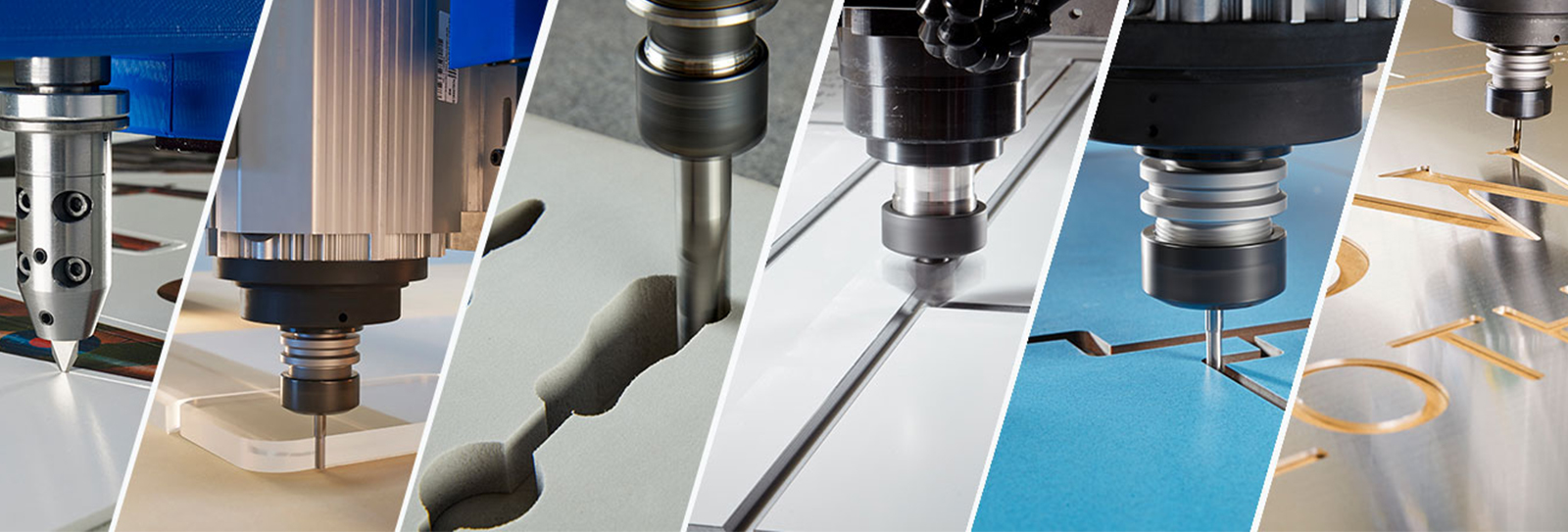

Various types of CNC Machine

CNC machines including CNC routers, CNC mills, CNC turning machines (or lathes), and Electrical Discharge Machining (EDMs).

CNC mills contain rotating cutting tools, which are moved to various areas of the workpieces to make cuts and can use to make different parts. CNC machines or lathes work the other way. It rotates the workpiece against any stationary cutting tool and is utilized to make cylindrical components.

CNC routers and CNC mills are similar, but contain less power and can’t cut the hardest materials. However, they can be faster than CNC mills.

EDM uses sparks instead of sharp cutting tools to cut material. No tangible contact is made between the workpiece and the tool.

CNC machines are defined by the number of axes. More axes suggest they can shift their tool or workpiece in several ways, providing greater cutting flexibility and the capacity to make more complex parts in a short time.

CNC Machining FAQ

Why you should choose CNC machining?

CNC machining is a versatile, fast, and accurate solution for making end-use metal and plastic parts; regardless of quantity, without investing in expensive set-ups or hard tooling. No matter how complex or simple the parts.

What materials are usable with CNC machining?

There is a range of materials usable in CNC machining China, which you can use like steel, brass, aluminum, titanium, copper as well as rigid plastics. Contact us to learn more about the kinds of materials that you can use.

Can I obtain tight tolerances CNC parts from Superapid?

Superapid is known as extraordinary compared to other CNC machining organizations in China regarding quality, speed, and client support. With top-notch CNC machines, we can undoubtedly accomplish +/ - 0.02mm of resistance and can even get inside +/ - 0.01mm. However, remember that it can affect the cost.