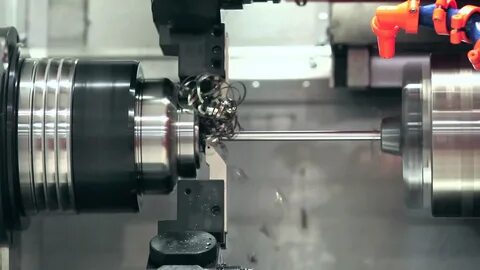

CNC Turning Services have become indispensable in the modern steel manufacturing industry. These services offer precision, efficiency, and cost-effectiveness unmatched by traditional methods. Let's explore ten compelling reasons why you should consider CNC Turning Services for your steel manufacturing needs.

1. Precision and Accuracy

- Micron-level precision: CNC machines deliver parts with tolerances measured in microns, ensuring optimal performance in critical applications.

- Consistent quality: Reduces defects, rework, and scrap rates, leading to higher yields.

- Improved product performance: Precise parts enhance product functionality, reliability, and longevity.

2. Enhanced Efficiency

- Rapid production cycles: CNC machines operate at high speeds, significantly reducing production time.

- Automated processes: Minimize manual intervention, leading to increased productivity and reduced labor costs.

- Shorter lead times: Deliver products to market faster, gaining a competitive advantage.

3. Cost-Effectiveness

- Reduced labor costs: Automation replaces manual labor, leading to significant cost savings.

- Optimized material usage: CNC machines precisely remove material, minimizing waste and reducing costs.

- Improved resource allocation: Efficient production processes allow for better utilization of resources.

4. Versatility

- Wide range of materials: Handles various steel alloys, stainless steel, and other metals with ease.

- Complex part production: Creates intricate shapes and designs with precision.

- Adaptability to changing demands: Handles diverse project requirements and batch sizes.

5. Repeatability

- Consistent part quality: Produces identical parts time after time, ensuring product reliability.

- Reduced inspection time: Consistent quality minimizes the need for extensive quality control.

- Improved customer satisfaction: Delivers products that meet or exceed customer expectations.

6. Complex Part Production

- Intricate geometries: Creates parts with complex shapes and features that are difficult to achieve with traditional methods.

- Enhanced product functionality: Produces parts with specific tolerances and surface finishes.

- Reduced assembly time: Complex components often require less assembly due to CNC machining.

7. Material Optimization

- Waste reduction: Precise cutting minimizes material scrap, contributing to sustainability.

- Cost savings: Reduces raw material consumption and related expenses.

- Lean manufacturing principles: Aligns with efficient production practices.

8. Automation

- Increased productivity: Machines operate continuously without interruptions, maximizing output.

- Consistent quality: Reduces human error, leading to improved product consistency.

- 24/7 operation: Enables round-the-clock production.

9. Safety

- Reduced workplace hazards: Automated processes minimize operator exposure to risks.

- Improved employee safety: Creates a safer working environment.

- Compliance with safety regulations: Adheres to industry safety standards.

10. Scalability

- Flexible production: Handles both small and large production volumes efficiently.

- Adapts to changing market demands: Scales operations up or down as needed.

- Supports business growth: Provides the capacity for increased production.

Last Word

CNC Turning Services offer a multitude of advantages for steel manufacturing. From precision and efficiency to cost-effectiveness and scalability, these services are transforming the industry. By embracing CNC turning, manufacturers can enhance their operations, improve product quality, and gain a competitive edge.