CNC Machining China has become a global powerhouse in precision manufacturing. This advanced technology has revolutionized industries, from aerospace to automotive. But what exactly is CNC machining, and how does it work?

Let's explore this comprehensive guide to understand the intricacies of this process.

Understanding CNC Machining

CNC machining is a computer-controlled manufacturing process used to create precise parts from a variety of materials. It involves using a computer to control machine tools, such as lathes, mills, and routers, to shape and cut materials into desired shapes.

How Does CNC Machining Work?

The CNC machining process involves several key steps:

- Computer-Aided Design (CAD): Engineers create a digital 3D model of the desired part using CAD software.

- Computer-Aided Manufacturing (CAM): CAM software translates the CAD model into instructions for the CNC machine.

- Machine Setup: The CNC machine is programmed with the instructions and the workpiece is securely clamped in place.

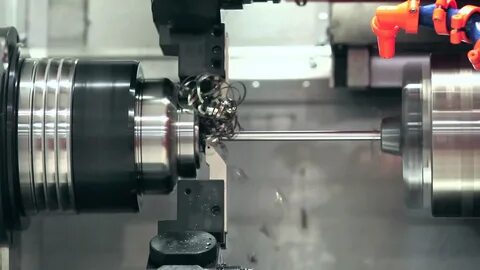

- Cutting Process: The machine's cutting tools remove material from the workpiece to create the desired shape.

- Inspection: The finished part is inspected to ensure it meets the specified tolerances and quality standards.

Types of CNC Machining

There are several types of CNC machining processes, each with its own unique capabilities:

- Milling: Uses a rotating cutter to remove material from a workpiece.

- Turning: Uses a rotating spindle to shape cylindrical or conical parts.

- Drilling: Creates holes in a workpiece using a rotating drill bit.

- Laser Cutting: Uses a laser beam to cut through materials with precision.

- Waterjet Cutting: Uses a high-pressure water jet to cut through various materials.

Advantages of CNC Machining

CNC machining offers numerous advantages over traditional manufacturing methods:

- Precision and Accuracy: CNC machines can produce parts with extremely high precision and accuracy.

- Efficiency: CNC machining is highly efficient, reducing production time and costs.

- Versatility: CNC machines can process a wide range of materials and create complex shapes.

- Automation: CNC machining is highly automated, reducing the need for human intervention.

- Repeatability: CNC machines can consistently produce identical parts, ensuring quality and consistency.

Applications of CNC Machining

CNC machining is used in a variety of industries, including:

- Aerospace: Manufacturing aircraft parts, such as engine components and landing gear.

- Automotive: Producing engine blocks, transmission parts, and other automotive components.

- Medical: Creating medical devices, implants, and prosthetics.

- Electronics: Manufacturing components for electronic devices, such as circuit boards and enclosures.

- Tool and Die Making: Producing precision tools and dies for manufacturing processes.

Future of CNC Machining

CNC machining technology continues to evolve, with advancements in software, hardware, and materials. Future trends include:

- Additive Manufacturing: Combining CNC machining with additive manufacturing techniques for hybrid production.

- Internet of Things (IoT): Integrating CNC machines with IoT technology for real-time monitoring and control.

- Artificial Intelligence (AI): Utilizing AI for process optimization, predictive maintenance, and quality control.

Last Word

CNC machining is a vital manufacturing process that enables the production of high-precision parts across various industries. Its efficiency, versatility, and accuracy make it an indispensable tool for modern manufacturing. As technology advances, CNC machining will continue to play a crucial role in shaping the future of manufacturing.