CNC Turning Services are critical in modern manufacturing. These services involve using computer-controlled machines to shape materials into precise components. The process is essential for creating parts used in various industries, including automotive, aerospace, and medical devices. CNC turning is likely involved if you’ve ever wondered how high-precision parts are made.

strong>Understanding CNC Turning

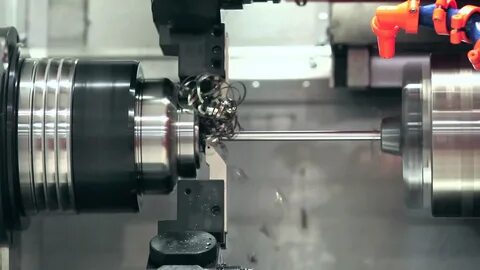

CNC turning is a process in which a piece of material, usually metal or plastic, is rotated while a cutting tool shapes it. The cutting tool moves in different directions to remove material from the rotating workpiece and form it into the desired shape. The machine’s computer program controls every move, ensuring accuracy to the smallest detail.

Key Features of CNC Turning Services

- High Precision: CNC turning offers exceptional accuracy, often within microns.

- Consistency: Every piece produced is identical, which is crucial for industries requiring tight tolerances.

- Versatility: CNC turning can handle a variety of materials, from metals to plastics.

- Speed: Once programmed, the machine can produce parts quickly and efficiently.

CNC turning is particularly effective for making cylindrical parts like shafts, screws, and even complex shapes with grooves and threads. The precision and consistency make it the go-to choice for industries that cannot afford errors.

The Importance of CNC Turning in Manufacturing

Manufacturing requires precision, and CNC turning delivers that with reliability. The automotive industry, for example, relies on CNC turning to produce engine components that must fit perfectly and function flawlessly.

In aerospace, even the slightest error can lead to catastrophic failure, so precision is non-negotiable. Medical devices also depend on CNC turning to create components that meet strict safety and performance standards.

- Automotive: Producing engine components and transmission parts with high precision.

- Aerospace: Creating components for aircraft that require extreme accuracy.

- Medical: Manufacturing surgical instruments and implants with exacting standards.

Statistics show that the global market for CNC machines is expected to reach $100 billion by 2025, driven by the demand for high-precision manufacturing.

How CNC Turning Services Work

The process begins with a detailed design, usually created using CAD (Computer-Aided Design) software. This design is then translated into a set of instructions that the CNC machine follows. The material is loaded onto the machine, and the turning process begins. The computer controls the cutting tool’s movements, ensuring each cut is made precisely as specified in the design.

Steps in CNC Turning

- Designing: Creating a detailed CAD model of the part.

- Programming: Converting the design into machine-readable code.

- Setting Up: Loading the material and calibrating the machine.

- Turning: The machine rotates the material and shapes it according to the design.

- Inspection: Checking the final product for accuracy and quality.

These steps ensure that each part produced meets the required specifications. CNC turning is also highly efficient, with machines capable of running continuously with minimal human intervention.

Advantages of CNC Turning Services

CNC turning offers several advantages over traditional manufacturing methods. One of the most significant is its ability to produce complex shapes that would be difficult or impossible to achieve manually.

The process is also highly repeatable, meaning once a machine is set up, it can produce hundreds or even thousands of identical parts with no variation.

- Complex Shapes: CNC turning can create intricate designs that manual processes cannot.

- Repeatability: The same design can be produced repeatedly with exact precision.

- Cost-Effective: While the initial setup may be costly, the ability to mass-produce parts reduces overall costs.

- Material Efficiency: CNC machines are programmed to use only the necessary material, minimizing waste.

The accuracy and efficiency of CNC turning make it a valuable service in today’s manufacturing landscape.

Future of CNC Turning Services

As technology advances, CNC turning services continue to evolve. Integrating AI and machine learning makes these machines smarter and more efficient. They can now adapt to real-time changes in the manufacturing process, reducing errors and increasing productivity.

Also, advancements in materials science mean that CNC machines can now work with a broader range of materials, opening up new possibilities for innovation.

- AI Integration: Machines that learn and improve over time.

- Material Advancements: Working with more diverse and advanced materials.

- Increased Automation: Less human intervention, leading to faster and more reliable production.

These developments ensure that CNC turning will remain a manufacturing cornerstone for years.

strong>Final Words

CNC Turning Services play a vital role in producing high-precision components used across various industries. CNC turning offers unmatched accuracy, efficiency, and versatility from the initial design to the final product. As technology advances, these services will only become more integral to manufacturing, providing even greater capabilities and applications.