CNC Machining Services China have become an integral part of modern manufacturing. This precise and efficient technique has revolutionized the way products are created, offering unmatched accuracy and customization. In this comprehensive guide, we'll explore the ins and outs of CNC machining, from its basics to its diverse applications.

strong>Understanding CNC Machining

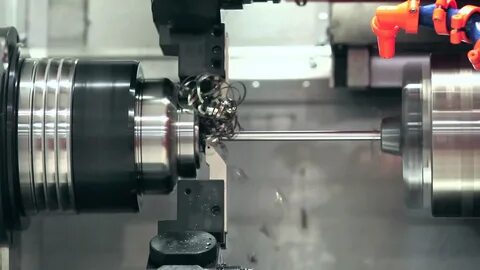

CNC machining, short for Computer Numerical Control machining, is a manufacturing process that uses computer-controlled machines to shape materials precisely. These machines, equipped with cutting tools, can create complex shapes and intricate details with exceptional accuracy.

- Versatility: CNC machining can work with a wide range of materials, including metals, plastics, and composites.

- Precision: The computer-controlled process ensures high levels of accuracy and consistency.

- Automation: CNC machines can operate with minimal human intervention, increasing efficiency.

- Customization: Complex shapes and intricate details can be easily created.

Types of CNC Machining

There are several types of CNC machining processes, each with its own unique capabilities:

- Milling: Uses a rotating cutter to remove material from a workpiece.

- Turning: Creates cylindrical shapes by rotating the workpiece against a cutting tool.

- Drilling: Creates holes in materials using a rotating drill bit.

- Grinding: Removes material from a workpiece using an abrasive wheel.

- Laser Cutting: Uses a laser beam to cut through materials with precision.

Benefits of CNC Machining

CNC machining offers numerous benefits to manufacturers:

- Increased Efficiency: Automation reduces labor costs and improves production speed.

- Improved Accuracy: CNC machines produce parts with exceptional precision and consistency.

- Reduced Waste: Precise cutting reduces material waste.

- Versatility: CNC machining can create a wide range of parts and components.

- Customization: Complex shapes and intricate details can be easily achieved.

Applications of CNC Machining

CNC machining is used in various industries, including:

- Automotive: Manufacturing engine parts, transmission components, and body panels.

- Aerospace: Creating parts for aircraft, spacecraft, and missiles.

- Medical: Producing medical devices and implants.

- Electronics: Manufacturing components for computers, smartphones, and other electronic devices.

- Industrial Machinery: Creating parts for industrial machinery and equipment.

Choosing a CNC Machining Service

When selecting a CNC machining service, consider the following factors:

- Experience: Look for a company with a proven track record in CNC machining.

- Capabilities: Ensure the company has the necessary equipment and expertise to handle your specific requirements.

- Quality Standards: Check if the company adheres to quality control standards.

- Delivery Times: Inquire about their lead times and ability to meet deadlines.

- Cost: Compare pricing and payment terms to find the best value.

Future Trends in CNC Machining

CNC machining technology continues to evolve, with exciting advancements on the horizon:

- Additive Manufacturing: Combining CNC machining with 3D printing for complex part creation.

- Artificial Intelligence: Integrating AI to optimize processes and improve efficiency.

- Nanotechnology: Applying CNC machining to create tiny components for nanotechnology applications.

strong>Final Words

CNC machining has become an indispensable tool for modern manufacturing. Its precision, efficiency, and versatility make it a valuable asset for businesses across various industries. By understanding the basics of CNC machining and carefully selecting a service provider, you can leverage this technology to produce high-quality parts and components.