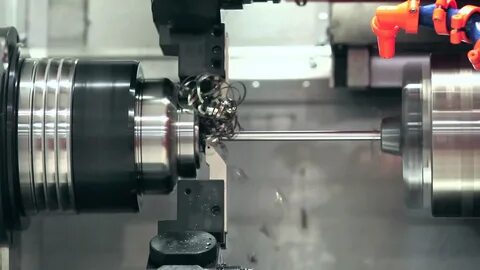

In the fast-growing technological world of today, modern tools and techniques are now dominating the industry. Indeed, one of the many such tools catering to path-making use is Computer Numerical Control machining, also known as CNC machining.

The advent of CNC machining has significantly transformed the manufacturing sector industries, such as aerospace, automotive, healthcare, and consumer electronics. The CNC machining center devices have transformed innovative ideas into reality.

The upcoming paragraphs throw some further light on the importance of CNC machining and how CNC machining particularly highlights the modern world.

What is CNC Machining

CNC machining is a process that encapsulates accurate control of machining spare parts and tools. This the core concept that you need to keep in mind.

The above-mentioned process is totally different from the conventional machining that requires human handling. CNC machining is based on computer-aided design techniques and machine automation. This helps in executing complex machining tasks and unprecedented efficiency. The precision helps CNC machining handlers to manufacture top-quality prototypes and components with:

- Repeatability

- Reliability

- Consistency

Advantages of CNC Machining

There are numerous benefits of CNC machining and the foremost is versatility. It doesn’t matter whether its grinding, drilling, or milling, CNC machining is an able technology to handle versatile materials, including exotic alloys, composites, and metals

Innovative Designs

Moreover, CNC machining can enable engineers and technicians to find innovative prototype designs that were once seen as impossible to create. Today, you can make simulation tools, CAD tools, optimized CNC structures, and detailed shapes with ease. Innovative CNC machining gives you the required flexibility for product development and enables you to be more creative in design creation.

Scalability

Scalability is also one of the top factors in the increasing popularity of CNC machining. Whether your organization needs mass manufacturing or instant prototyping for product validation; CNC machining is simply the way to go. You can easily mass-scale from small projects to giant-sized manufacturing volumes. The power of scalability makes sure you can adapt to dynamic market trends without compromising lead time and product quality.

Cost-Efficiency and Production Efficiency

Further, two more factors also amplifies the significance of CNC machining. One is budge-friendliness and the other is driving efficiency. CNC machines can now enable you to reduce wastage to almost nil and automate tasks that are repetitive. Moreover, CNCN machining can do complex operations in one step further, which makes secondary operations redundant. You get your processes streamlined in less cost with quality CNC machining operations.

Speed

Further, speed or pace of production has also got significance in today’s manufacturing arena. CNC machining is also at par in this department and provides you agility. You can swiftly create designs, aptly respond to client requests, and go hand in hand with market trends. Whether its prototype validity or agile production, CNC machining will always be your trusted manufacturing partner.

Wrap Up

In conclusion, CNC machining is more than just a manufacturing process; it's a catalyst for innovation, efficiency, and progress. By bridging the gap between imagination and reality, CNC machining empowers businesses to bring their ideas to life and meet the demands of an ever-changing world. As we continue to push the boundaries of what's possible, CNC machining will undoubtedly remain at the forefront of technological innovation, driving growth and shaping the future of manufacturing.